Application areas

AIRPRO, during the yearsof the founders' experience, could have a good masteryfrom different sectors of international industry.

New at AIR-PRO

Deodorization by ozone generation (Washing tower)

The treatment of bad odors is one of the most efficient processes for eliminating all bad odors. The treatment of bad odors with ozone generators is a technique used mainly in the food sector or for the treatment of plant waste from animal products (fish waste, ...)

Ozone allows extremely rapid elimination by oxidation of elements or constituents such as hydrogen sulfide (H2S)

For deodorizing and cleaning heavy air streams, ozone is a very efficient and easy-to-use technique. Bad odors are organic matter suspended in the air. Ozone allows neutralization by oxidation of pollutants such as hydrogen sulfide (H2S), cooking steam, processing of fish and meat, frying.

AIRPRO is developing an optimal system which ensures the suction of dust during the sandblasting operation.

Filtration is carried out by a dust collection filter with a pneumatic cleaning sleeve sized according to the size of the working chamber. A scraping and sand collection system is a complement to be placed for the recovery of waste.

The food industry in general is the most demanding industry in terms of health. These problems can be remedied by dust collection filters, pneumatic transport, ventilation, industrial cleaning and other disciplines.

AIRPRO has extensive experience in this field following several solutions implemented in different sectors.

Fields of application

Our intervention in the field of Steel industry

In the field of steel construction, there are several sources of dust and smoke. Plasma cutting machines, welding stations, materials handling, and painting give off a large amount of toxic smoke and dust that is harmful to health.

In the field of steel construction, there are several sources of dust and smoke. Plasma cutting machines, welding stations, materials handling, and painting give off a large amount of toxic smoke and dust that is harmful to health.

AIRPRO, put at your disposal its experience to set up fume extractors, dedusting installations and adequate ventilation systems.

Our intervention for

a baby diaper production line

The dust generated by coating production lines are usually polyester. AIRPRO has developed a drum dust filter, which meets the requirements of the sector.

The waste separation is done in two parts, first by using scrapers cleaning the media from the drum, secondly by using antistatic filter cartridges and a pneumatic cleaning system.This combination increases the filtration performance and the required vacuum of the production machine.The objective of this combination is to improve both air quality and retain particles that should not be released into the atmosphere.

The choice of these filter elements can be made according to several criteria:

The identification of these parameters is our responsibility with the help of a survey that will enable us to have a total and sufficient idea.

Our intervention in the field of Sandblasting

Sand blasting is a process for cleaning the surface of a material by a phenomenon generated by a jet of sand and compressed air.Sand blasting is most often carried out in the iron and steel industry or in the transformation of materials such as foundries.

Blasting is generally carried out on steel, cast iron and metal alloys in general, but also on other materials such as wood, ceramics, stone and marble, with industrial mechanical or construction applications.

In particular, it is a major source of dust, which causes a health problem for operators in close proximity and a source of pollution for the environment.Dust removal systems are adapted to this industrial process enabling the extraction, filtration and collection of waste.

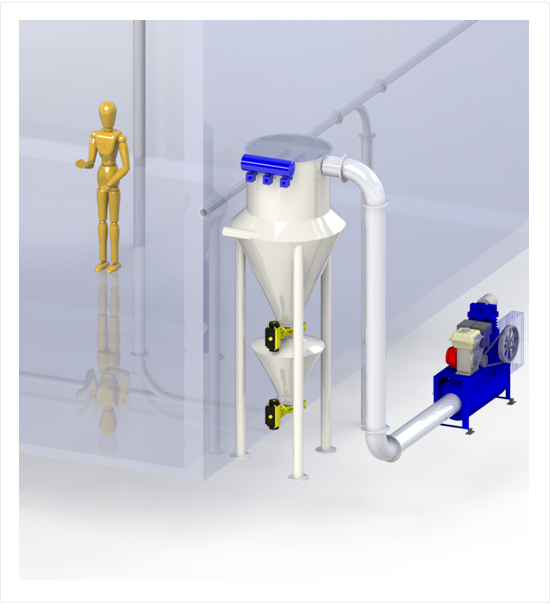

AIRPRO develops an optimal system that ensures the extraction of dust during the blasting operation.

The filtration is done by a dust filter with pneumatic cleaning sleeve, dimensioned according to the size of the working space.A scraping and sand collection system is a complementary system to be placed for the recovery of waste.

Our intervention in the foundry sector

Foundries are harmful workplaces.

A thorough study for fume extraction, furnace chimney stack routes, dedusting, and ventilation of work areas must be implemented to ensure the safety of operators and protect the environment.

Pollution control techniques in foundry plants have become mandatory, the international requirements for improving working conditions and environmental protection and the strengthening of regulations help to develop ways of reducing the release of pollutants.

Whether the installations are intended for environmental protection, personnel safety or product recovery, AIRPRO accompanies you during the different phases of your project, with its knowledge and experience to give you the best solutions for dust removal and adequate aeration in your production plants or storage rooms.

In this discipline, we adapt our technical solutions to the requirements of the sector, and also to the specificities of each customer, which leads us each time to a customized solution with guaranteed results.

Our intervention in the wood sector

A dust removal system is indispensable for the wood industry.

To protect the operators as well as to increase the screw life of the machines and the protection of the environment.

A dust-removal system at the source is recommended for production lines, which guarantees a good product quality.

The efficiency of wood dust extraction by means of mobile vacuum cleaners is not recommended.

The wood sector is very competitive. The production cost is a very important factor that can even influence the existence of companies.

The performance of the dust collection installations has a direct effect on the production performance and on the costs of preventive and corrective maintenance.

Our intervention in the field of Detergents

Detergent production lines are a source of dust and noxious odours, they are the cause of many diseases and respiratory problems.

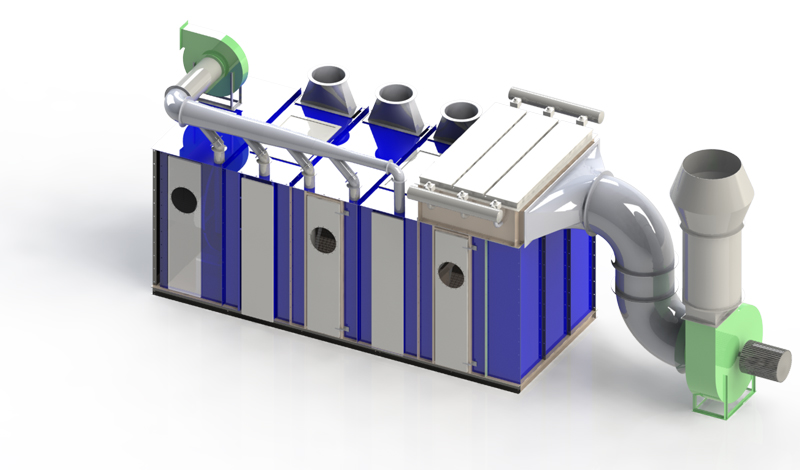

To remedy these problems, improve working conditions and protect the environment from these waste products, a complete system of waste collection, routing, filtration and recovery must be put in place.

AIRPRO with its experienced team can treat these difficult products due to the humidity and chemical characteristics of the raw materials.

The solutions of dust aspiration, aeration and recovery of products enables a better protection of the operators and guarantees to the contractor a better risk management and protection of the environment.

Our intervention inthe cement industry

With the know-how and years of experience in cement plants AIRPRO is at your disposal to ensure the right dimensioning of your Air Transfer systems ( pneumatic transport in the dilute phase, pneumatic transport in the dense phase, rails...), Dust removal filters, top silo filters, ventilation of the electrical cabinets, overpressure in the rooms as well as the ventilation and air conditioning of the working spaces.

All cement production processes generate dust such as: crushing, grinding, screening and bulk transfer.

The hooding and the study of an efficient installation of a dust collection filter and a balanced suction network is necessary for the proper functioning of the cement production lines.

Cement plants must be equipped with several centralized cleaning systems, which makes waste collection easier and guarantees a clean space for the benefit of the operators and the life of the equipment.